Boring, Honing & Balancing Your Engine

Modifying and rebuilding engines makes a great passion project for people who love performance vehicles and those who want to breathe new life into beloved vehicles. Working with a machine shop to handle some of the more complicated parts of modifying and rebuilding your vehicle’s engine ensures that the job is done right, as mechanics at these shops have expert training and the right tools, components, and car accessories to ensure the precision needed. This is particularly important when it comes to boring, honing, and balancing an engine.

Modifying and rebuilding engines makes a great passion project for people who love performance vehicles and those who want to breathe new life into beloved vehicles. Working with a machine shop to handle some of the more complicated parts of modifying and rebuilding your vehicle’s engine ensures that the job is done right, as mechanics at these shops have expert training and the right tools, components, and car accessories to ensure the precision needed. This is particularly important when it comes to boring, honing, and balancing an engine.

Boring

Boring an engine involves using machines to widen and taper the cylinders. From a performance standpoint, boring an engine could give you more horsepower and torque, as it will change the engine’s displacement. Engine displacement refers to the swept volume of all pistons inside the cylinders of an engine. Displacement impacts how much fuel a cylinder draws in to create power, with high displacement engines drawing in more of the air and fuel mixture per revolution, resulting in a more powerful combustion.

Engine displacement plays an important role in determining how much horsepower and torque your engine produces and how fuel efficient it is. In general, the greater your engine’s displacement, the more power it can create. Lower displacement may result in greater fuel economy.

There’s actually a mathematical equation used to calculate displacement:

Engine displacement = π/4 * bore² * stroke * number of cylinders.

Displacement is just one factor that contributes to the power of your engine. Other factors include fuel delivery, valvetrain layout, forced induction, and ignition systems. In some countries, vehicles are taxed based on engine displacement.

Boring is also done when mechanics are restoring engines. With years of use, engine cylinders become worn out as friction stresses cause wear and tear. Boring out engine cylinders helps clear them of debris that can build up over years of use.

Boring an engine is best left to professional mechanics, as a botched job can lead to major problems. If the bore isn’t done correctly it can result in engine knock.

Boring an engine is best left to professional mechanics, as a botched job can lead to major problems. If the bore isn’t done correctly it can result in engine knock.

Stroking an engine is another method of increasing displacement. Engine stroking allows for greater displacement than boring, but it also requires great precision in picking the right car accessories and parts.

In engine stroking, a mechanic will alter the distance the piston travels in the cylinder bore. By increasing the distance the piston travels in the cylinder, a mechanic can increase engine displacement. Stroking the engine also increases torque by increasing the engine’s crankshaft arm or lever.

Honing

Honing involves using an abrasive to create a precision surface on a piece of metal. Honing is used in a variety of applications, such as finishing cylinders for automotive engines.

In cylinder honing, mechanics use a rotating tool equipped with abrasives to remove metal from the inside of a cylinder. Honing a cylinder helps to finish the surface of the cylinder’s interior to fit a certain diameter and shape. Honing is done after boring to smooth out any irregularities in the cylinder’s finish caused by boring.

Abrasives typically used in honing include silicon carbide and aluminum oxide. These abrasives are inexpensive and versatile. Lately, performance engine builders have increasingly turned to diamond abrasives. Mechanics like these abrasives better because they can hold a cutting edge longer than other forms of abrasives.

Getting honing right is important. A bad honing job may result in improper seating by piston rings that will inhibit oil flow, along with some other negative consequences.

Honing is difficult. The average shade-tree mechanic does not have the tools or technical skills to reproduce an OEM cylinder bore finish. In parts of the country with emissions testing, this can be a problem, as improperly honed cylinders might result in a vehicle failing an emissions test.

Balancing

Balancing your engine is another important part of rebuilding or modifying an engine. Your engine’s balance affects many aspects of its operations, including its:

- Longevity

- Performance

- Power

- Fuel efficiency

- Noise

- Vibration

- Environmental impact

In short, balancing your engine equalizes the reciprocating and rotating forces happening in your engine, allowing it to run smoother and enjoy greater utility and longevity. Many people don’t realize that their vehicles are powered by mini-explosions in the engine that occur during combustion. Balancing the engine helps to manage the impact of these reactions.

In short, balancing your engine equalizes the reciprocating and rotating forces happening in your engine, allowing it to run smoother and enjoy greater utility and longevity. Many people don’t realize that their vehicles are powered by mini-explosions in the engine that occur during combustion. Balancing the engine helps to manage the impact of these reactions.

One of the primary tasks involved in engine balancing is equalizing the weights of various parts. Mechanics must equalize the weights of the pistons, wrist pins, rings, connecting rods, rod bolts, and bearings to balance out the forces acting on the automobile’s crankshaft.

When balancing the engine, mechanics precisely weigh parts to determine which piston and rod are the lightest. Mechanics then machine the other rods and pistons to make them equal to the lightest one in the set.

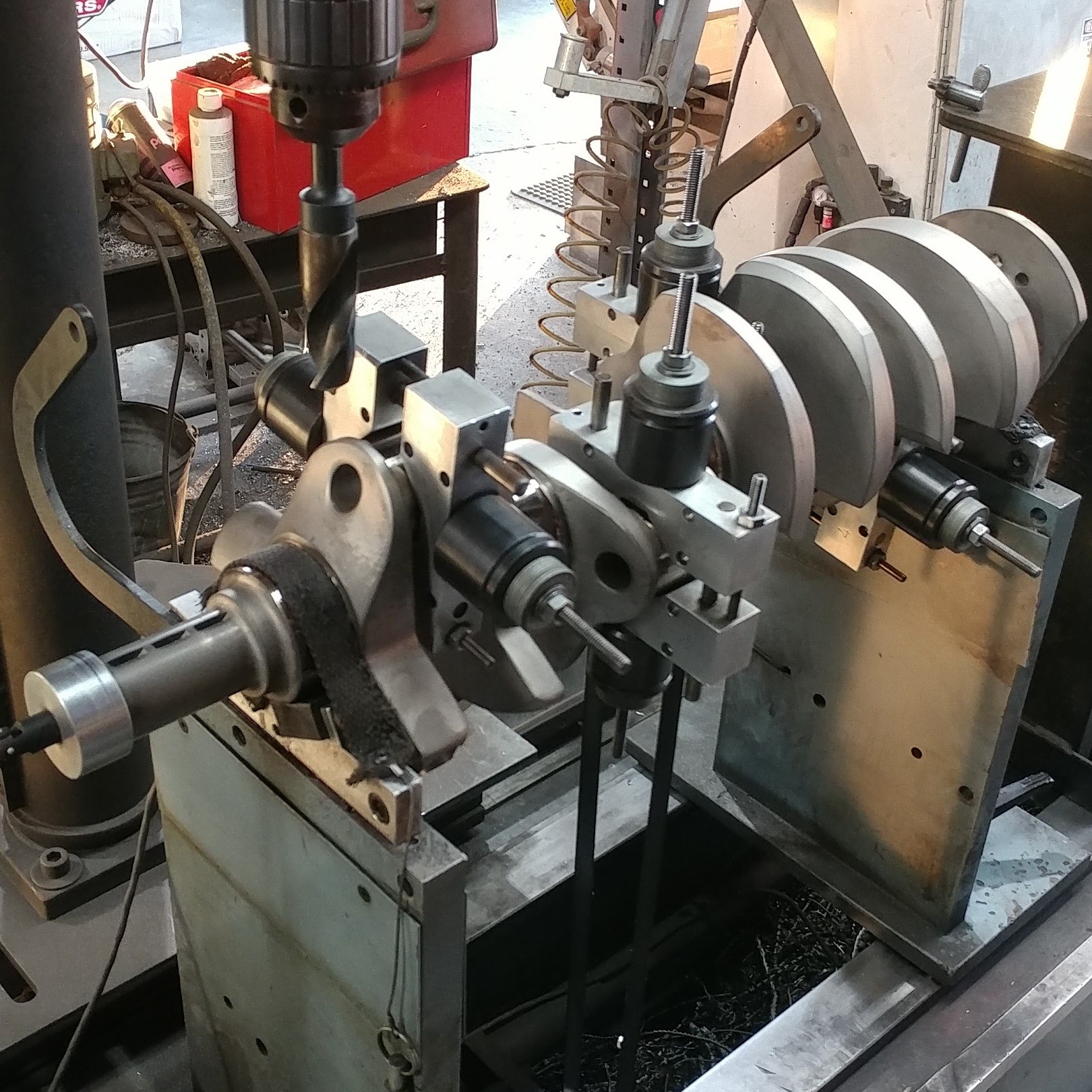

Next, rotating and reciprocating weights are evaluated in isolation from one another. Once the weights have been determined, bobweights that simulate all of the rotating weight and half the reciprocating weight are put together and clamped on each rod journal. The crankshaft is then placed on an engine balancer and spun.

In some cases, mechanics will try to overbalance or underbalance a crankshaft in order to minimize vibrations and harmonics in a certain rpm range.

Again, it’s important to have balancing work done by a skilled professional with the proper tools to ensure a very precise engine balancing job, particularly if you’re making performance upgrades to your vehicle.

Booming Automotive Aftermarket

Engine rebuilds and other aftermarket work is a booming industry in the U.S. Americans love their cars, and they love personalizing them with unique features or boosting their performance with engine and other modifications. In the U.S., the automotive aftermarket is estimated to be worth about $318.2 billion and employs more than 4 million people.

There’s a robust DIY movement among auto enthusiasts, but many of even the most die-hard do-it-yourselfers work with machine shops and other professional mechanic shops for the toughest auto jobs.

When choosing a machine shop for your engine repair or upgrade needs, be sure to ask the following questions:

Is this shop a well-established provider of the type of engine repairs or upgrades I need? How is its professional reputation in the community? If many of your friends and neighbors don’t have good things to say about the mechanic you’re considering doing business with, take it as a warning. Reputation is everything in this business. Shops that do good work get good word of mouth.

Is this shop a well-established provider of the type of engine repairs or upgrades I need? How is its professional reputation in the community? If many of your friends and neighbors don’t have good things to say about the mechanic you’re considering doing business with, take it as a warning. Reputation is everything in this business. Shops that do good work get good word of mouth.

Does this shop have the right tools for the job? This can be a little difficult for laypeople to assess. It might be worth your while to have a conversation with the shop you’re considering to find out what tools they use, and then do a little research.

Does the staff seem interested in its work? Auto enthusiasts can usually tell when their mechanic shares their enthusiasm vs. when they’re just doing a job. Mechanics who are enthusiastic about your project are more likely to put a little extra effort into it.

Team C Performance Center provides auto parts and a full-service machine shop for automotive enthusiasts in the Los Angeles area. In business since 1978, Team C Performance stocks hundreds of performance auto parts and car accessories from more than 150 manufacturers. The machine shop can help you with boring, honing, decking, resizing rods, valve jobs, complete engine rebuilds and much more. Visit today to find out how Team C Performance Center can help you create the vehicle you’ve always dreamed of owning.

Sources

1. https://itstillruns.com/bore-out-engine-cylinder-7500753.html

2. http://www.enginebuildermag.com/2002/11/the-smooth-science-of-cylinder-honing/

You must login to post comments.